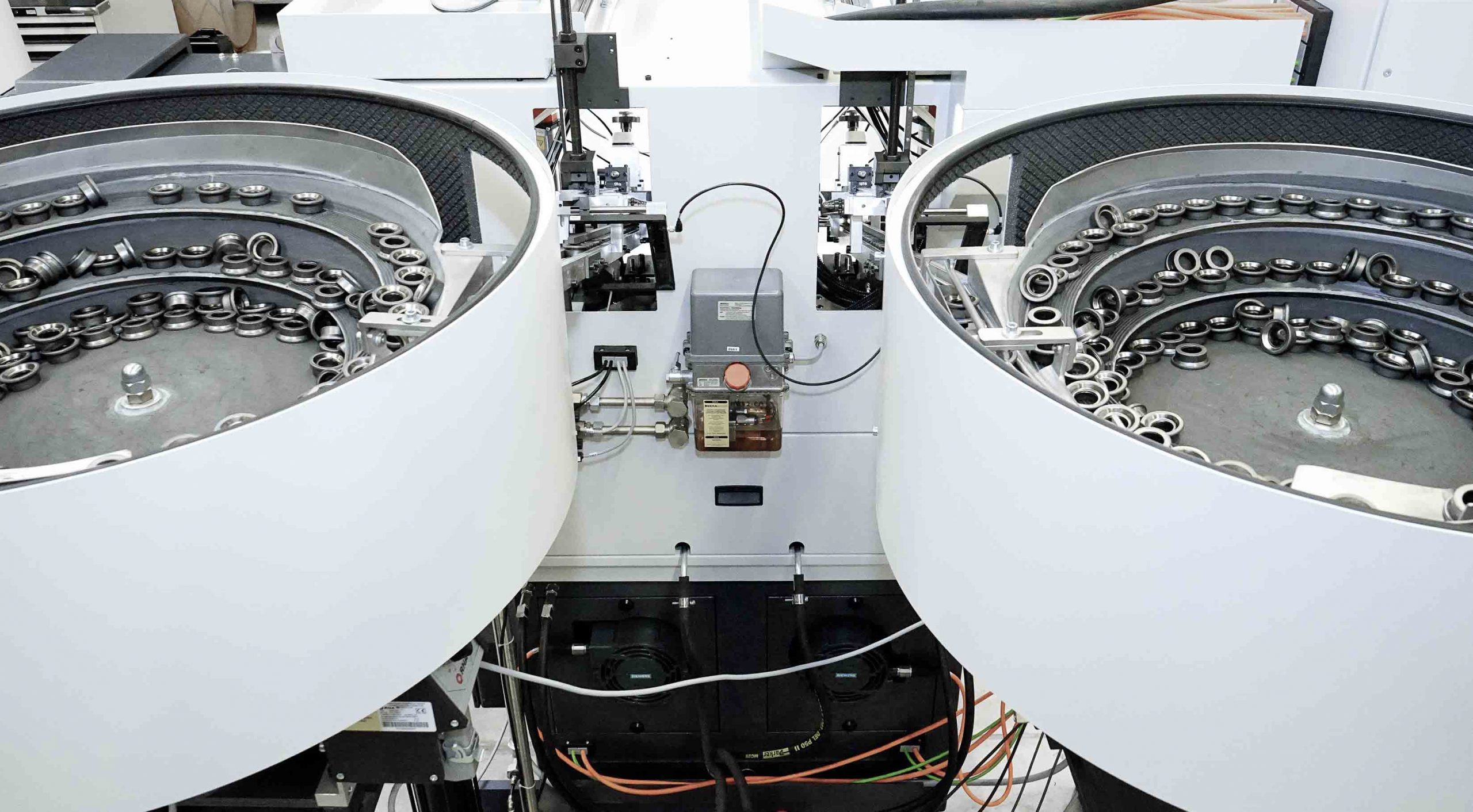

tm 20

cam-controlled twin spindle automatic lathe for second operation

Twofold or two-sided with turn over or transfer station: You have the choice!

tm 20 - cam-controlled twin spindle automatic lathe for second operation

The Audrema® tm 20 twin spindle automatic lathe for second operation combines speed and a high degree of repeat accuracy. One precise machine with significant short cycle times.

Technical specifications:

- Maximum standard part dimensions:

140 mm length (120 mm shank + 20 mm head)

30 mm diameter (versions on request) - Changing times with collet chucking:

Free drop < 1,0 s

Guided drop < 1,5 s - Changing times with three-jaw chucking:

Guided drop < 2 s - Performance of up to 35 parts per minute (up to 70 parts per minute in parallel operation)

- Maintenance-free precision spindle bearing

- PCL control for leading functions

- High performance drives up to 9 kW

- Independent and multiple variable camshaft rotation speed

- Mechanical feed cams

- Interchangeable chucking devices:

Pull collet chuck, push collet chuck, overhead chuck, power operated mandrel

- Optional clamping devices on request

- Multiple chucking is possible

- Interchangeable tool carriers:

Radial slides, cross slide radial-axial, multiple cross slide with guiding ruler, straight-turning slide - Optional spindle sleeve slide for drilling and threading

- Hydraulic unit for sphere turning

- Extensive program of feeding systems for parts with head, discs, rollers, pins, headless parts etc.

- Position detection and position change of parts in the feeder unit is possible

- Turn over or transfer station (two-sided processing)

- Double feeding system (twin spindle parallel operation)

The application of two feeing systems enables a doubling of performance. (double machine operation)